Nitrofreeze® Proof of Concept Case Study- Deburring Polysulfone (PSU) Our Cryogenic Deflashing and Deburring process adds value while reducing costs to customers by eliminating the need for hand trimming. Highlighted below is an actual customer part that has successfully undergone the Nitrofreeze® process. Material : Polysulfone (PSU) Description : Medical injection pen assembly Area for Concern : Exterior lettering (not shown) as...

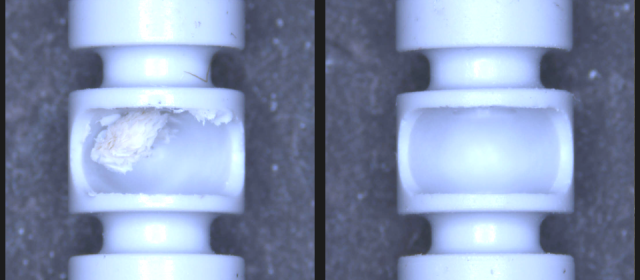

Read MoreNitrofreeze® Proof of Concept Case Study-Deflashing Silicone Our Cryogenic Deflashing and Deburring process adds value while reducing costs to customers by eliminating the need for hand trimming. Highlighted below is an actual customer part that has successfully undergone the Nitrofreeze® process. Material : Silicone Description : 60 duro baby blue silicone electrical grommet Area for Concern : OD parting line flash and through hole...

Read MoreNitrofreeze® Proof of Concept Case Study-Deburring Ertalyte® PET-P Our Cryogenic Deflashing and Deburring process adds value while reducing costs to customers by eliminating the need for hand trimming. Highlighted below is an actual customer part that has successfully undergone the Nitrofreeze® process. Material : Ertalyte® PET-P Description : Bearing Retainer Assembly Area for Concern : Critical Face Opening Results : Parts were...

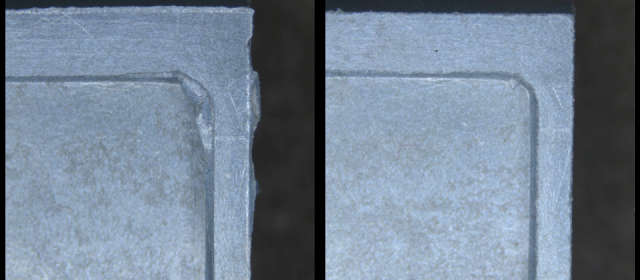

Read MoreNitrofreeze® Proof of Concept Case Study-Deflashing Nylon Our Cryogenic Deflashing and Deburring process adds value while reducing costs to customers by eliminating the need for hand trimming. Highlighted below is an actual customer part that has successfully undergone the Nitrofreeze® process. Material : Carbon Filled Nylon Description : Electrical Connector Area for Concern : Mold Flash Results : Mold flash removed along with...

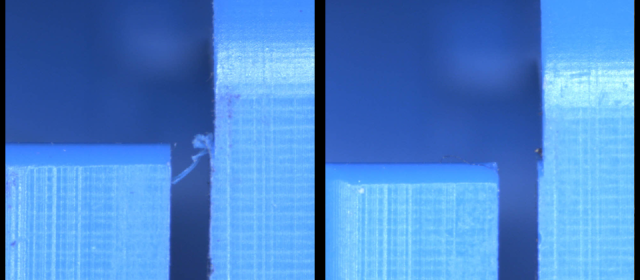

Read MoreMaterial : Silicone

Description : Blue X

Area for Concern : Parting line flash

Results : Cryogenic Deflashing successfully removed exterior parting line flash with no modifications to critical tolerances. All interior “x” flash removed near 100%. Surface finish remained unchanged without surface scratches or damage. The Cryogenic Deflashing process also appears to have removed unwanted lint and dust from the part.

Nitrofreeze provides cryogenic deflashing and deburring solutions across a variety of industries. Whether parts are molded or machined, Nitrofreeze has a solution. To learn more, please contact Bryce Trani at (800) 739-7949 or at [email protected].

Read More